TAG recommendation

TAG recommendation

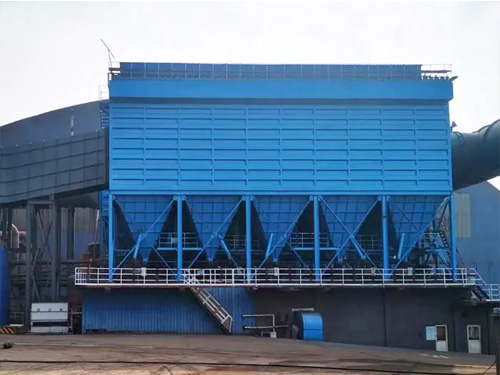

Boiler dust collectors are used for flue gas purification and dust recovery and reuse in coal-fired and oil-fired boilers.

Flue gas enters the Venturi through the flue gas inlet and is sprayed evenly with water at the throat entrance.Due to the high-speed movement of the flue gas,the sprayed water is melted into fine water mist to wet the ash in the flue gas.In this way,the ash and water droplets collide and condense,especially the fine dust can be dissolved by the water mist.The first dust removal and desulfurization are achieved,which make full preparations for the separation of ash.After that,the flue gas enters the cylinder,and the flue gas with a speed suitable to reduce the temperature continues to impact the lime water in the pool.The dust and SO2 in the flue gas react with the lime water in the pool to form sulfate,which sinks to the bottom of the water under the action of inertia,gravity,adhesion and cohesion to complete the first desulfurization process.The splashes and mist stirred up by the flue gas and the washed flue gas are lifted up by the fan at the same time,so that the flue gas and lime water fully react,and then enter the impeller dehydrator for separation with actual water as the main water.The water flows into the water pool through the drain pipe,and the flue gas completes the third dust removal and desulfurization.The purified gas is discharged into the atmosphere through the fan.The dedicated service has obvious effect on high-temperature smoke treatment and reduces the pollution of urban and rural coal-fired industrial boilers to the environment.

Contact:Mr Zhang

Tel:+86-15076757460

E-mail: lww_0601@163.com

WhatsApp:+86 13691372998

Our company adheres to the business philosophy of "quality as the basis, innovation as the fundamental, service as the life", vigorously develops new products, strives to open up new markets, and provides a broad development space for the development of the enterprise.